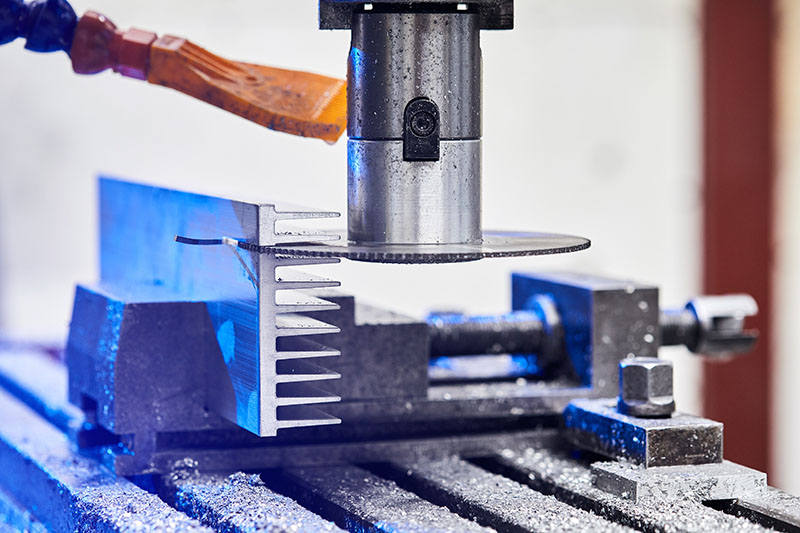

Cutting aluminium billet with machine. Circular milling machine cutting metal profile. Steel industry.

Precision cutting technologies have revolutionized the manufacturing industry, enabling companies to achieve unprecedented levels of accuracy and efficiency. As the demand for high-quality, customized products continues to rise, manufacturers are turning to advanced cutting techniques that provide not only precision but also flexibility in production. This article explores the various methods employed in precision cutting, ranging from laser and waterjet cutting to CNC machining, and highlights how these innovations are reshaping manufacturing processes across various sectors.

In an era where competitive advantage hinges on operational excellence and product quality, precision cutting plays a crucial role in optimizing production lines. By minimizing waste and maximizing material utilization, these cutting-edge technologies help manufacturers reduce costs while meeting stringent specifications. As we dive deeper into the world of precision cutting, we will examine the benefits, challenges, and future trends that are driving the evolution of this essential manufacturing capability.

Advancements in Precision Cutting Technologies

Precision cutting technologies have made significant strides in recent years, showcasing innovative approaches such as fiber laser cutting and abrasive waterjet cutting. Fiber lasers offer unparalleled precision and efficiency, especially when working with thin metals, while waterjet cutting excels in materials that cannot withstand the high temperatures produced by other methods. These advancements allow manufacturers to create intricate designs and complex geometries, leading to an expansion in creative possibilities. Furthermore, CNC machining automation has streamlined production processes, ensuring consistent quality and speed, ultimately resulting in shorter lead times and enhanced customer satisfaction.

Future Trends in Manufacturing Processes

Looking ahead, the future of precision cutting is poised for growth, with ongoing research and development focused on integrating artificial intelligence and machine learning into cutting operations. These technologies will enable predictive maintenance and real-time monitoring, further enhancing cutting accuracy and reducing downtime. As the manufacturing landscape continues to evolve, the role of precision cutting will become increasingly paramount. The insight into The Evolution of Precision Cutting in Manufacturing also hints at how traditional methods will be augmented by more sophisticated techniques, creating a hybrid approach that optimizes performance and meets diverse industry needs.

In conclusion, precision cutting is not merely a trend but a fundamental pillar of modern manufacturing that continues to evolve in response to industry demands. The integration of advanced technologies such as fiber lasers, waterjet systems, and intelligent automation is revolutionizing how products are conceptualized and produced, fostering an environment that prioritizes innovation and quality. As manufacturers embrace these cutting-edge methods, they benefit from greater efficiency, reduced waste, and enhanced design capabilities, ultimately leading to stronger market positions. The future will likely see even deeper integration of smart technologies, allowing for more adaptive and responsive production environments that can meet the challenges of a rapidly changing marketplace. Embracing precision cutting is essential for any manufacturer aiming to thrive in this competitive landscape, as it not only enhances operational performance but also paves the way for groundbreaking possibilities in product development.